-

Telecommunication

-

Fiber Optic Cables

-

< div class="menu-icon">

Conventional Cables

Conventional Cables

-

< div class="menu-icon">

OPGW

OPGW

-

< div class="menu-icon">

ADSS

ADSS

-

< div class="menu-icon">

Submarine

Submarine

-

< div class="menu-icon">

WTC (World's Highest Density)

WTC (World's Highest Density)

-

< div class="menu-icon">

-

Optical Fibers

-

< div class="menu-icon">

Single Mode

Single Mode

-

< div class="menu-icon">

Multi Mode

Multi Mode

-

< div class="menu-icon">

Specialty Fibers

Specialty Fibers

-

< div class="menu-icon">

-

Fiber Splicing Machines & Related Products

-

< div class="menu-icon">

Telecommunication Fibers

Telecommunication Fibers

-

< div class="menu-icon">

Specialty Fibers

Specialty Fibers

-

< div class="menu-icon">

-

Optical Test Equipment

-

< div class="menu-icon">

Optical Spectrum Analyzers

Optical Spectrum Analyzers

-

< div class="menu-icon">

Optical Time Domain Reflectometers/OTDR

Optical Time Domain Reflectometers/OTDR

-

< div class="menu-icon">

Optical Wavelength Meters

Optical Wavelength Meters

-

< div class="menu-icon">

Moduler Manufacturing Test System

Moduler Manufacturing Test System

-

< div class="menu-icon">

Portable Power Meters & Light Sources

Portable Power Meters & Light Sources

-

< div class="menu-icon">

Portable Ethernet Testers

Portable Ethernet Testers

-

< div class="menu-icon">

-

Rf Products & Telecom Towers

-

< div class="menu-icon">

Connectors & Adaptors

Connectors & Adaptors

-

< div class="menu-icon">

Cable Assemblies

Cable Assemblies

-

< div class="menu-icon">

Test Equipment

Test Equipment

-

< div class="menu-icon">

Antennas

Antennas

-

< div class="menu-icon">

Site Solutions

Site Solutions

-

< div class="menu-icon">

Tools & Accessories

Tools & Accessories

-

< div class="menu-icon">

Telecom Towers

Telecom Towers

-

< div class="menu-icon">

-

Copper Telecommunication Cables

-

< div class="menu-icon">

Copper Telecommunication Cables

Copper Telecommunication Cables

-

< div class="menu-icon">

-

Installation Accessories For F/O Cables

-

< div class="menu-icon">

Installation Accessories For F/O Cables

Installation Accessories For F/O Cables

-

< div class="menu-icon">

-

Tools

-

< div class="menu-icon">

For Coaxial Cables

For Coaxial Cables

-

< div class="menu-icon">

For Fiber Optic Cables

For Fiber Optic Cables

-

< div class="menu-icon">

For Electrical Cables

For Electrical Cables

-

< div class="menu-icon">

For Power Utilitiy Cables

For Power Utilitiy Cables

-

< div class="menu-icon">

-

Fiber Inspection & Cleaning Products

-

< div class="menu-icon">

Fiber Inspection

Fiber Inspection

-

< div class="menu-icon">

Cleaning Kits

Cleaning Kits

-

< div class="menu-icon">

Push-Type Cleaners

Push-Type Cleaners

-

< div class="menu-icon">

Reel-Type Cleaners

Reel-Type Cleaners

-

< div class="menu-icon">

Fiber Optic Cleaning Fluids

Fiber Optic Cleaning Fluids

-

< div class="menu-icon">

Wipes & Cleaning Cards

Wipes & Cleaning Cards

-

< div class="menu-icon">

Cleaning Sticks,Tips & Swabs

Cleaning Sticks,Tips & Swabs

-

< div class="menu-icon">

-

Optical Components

-

< div class="menu-icon">

Central Office Application

Central Office Application

-

< div class="menu-icon">

Optical Cabinets

Optical Cabinets

-

< div class="menu-icon">

High-Rise Building Solutions

High-Rise Building Solutions

-

< div class="menu-icon">

Demarcation Boxes & Optical Outlets

Demarcation Boxes & Optical Outlets

-

< div class="menu-icon">

Optical Splitters

Optical Splitters

-

< div class="menu-icon">

Optical Closures

Optical Closures

-

< div class="menu-icon">

-

-

Energy

-

Mining

_4f0de13d-6191-4f2b-8da7-4d4706281433.png)

- Fiber In Medical

- Solar Cell

Telecommunication Fibers

Clad Alignment Fusion Splicer 41S+ Kit

Product code M6KBGK

The 41S+ is now equipped with "ACTIVE FUSION CONTROL TECHNOLOGY" and "ACTIVE BLADE MANAGEMENT TECHNOLOGY" to maintain consistent low loss splicing results. These two technologies, allow customers to achieve more stable low-loss splicing, reducing the need for rework and re-splicing.

Features

Active Fusion Control Technology

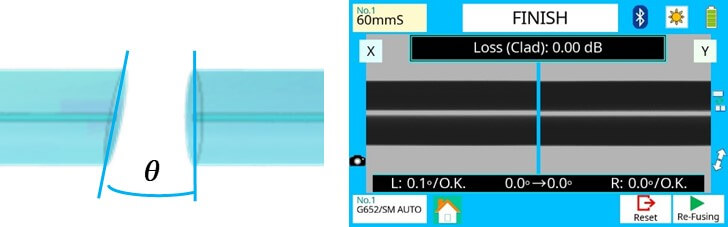

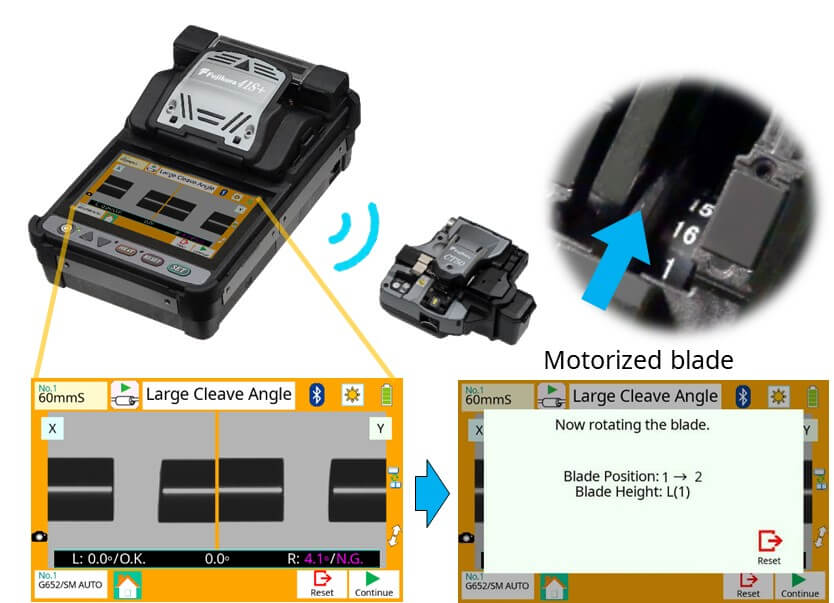

1. Active Fusion control by cleave condition

One of main causes of high splice loss is bad cleave end face quality. The 41S+ analyzes the condition of both L and R cleave end faces and applies optimal fusion control. This new technology improves splice loss significantly and greatly reduces needs for rework.

Splice loss with large cleave angle : 3 <θ< 5 degree

*G.652 splicing result measured with a cut-back method. The splicing result changes depending on the fiber type and fiber characteristics.

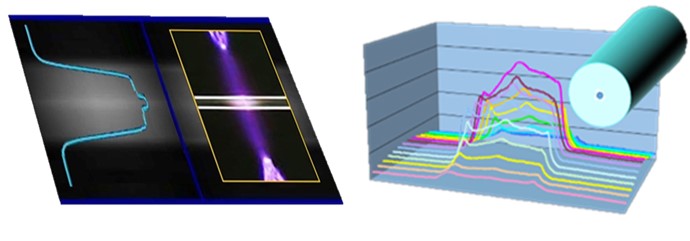

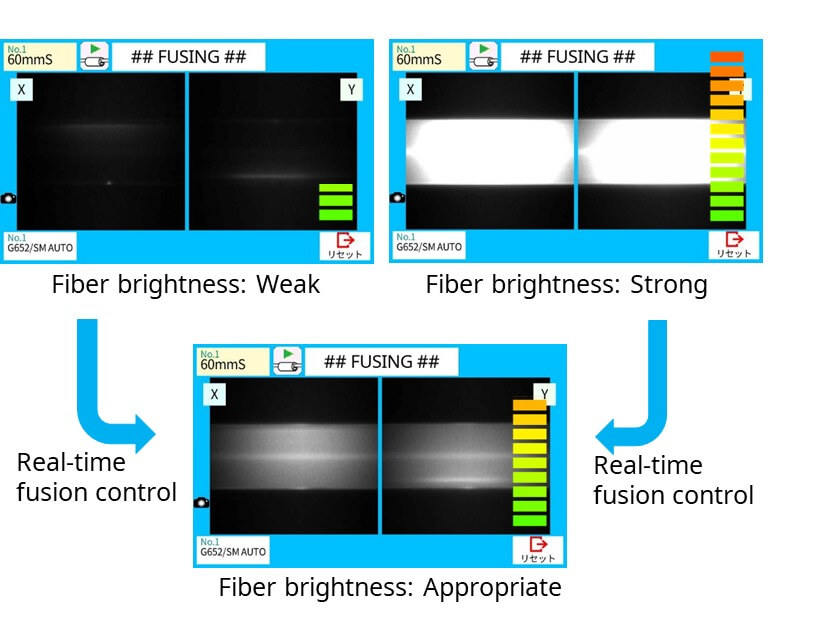

2. Active Fusion control by fiber brightness

Fusion is easily affected by changes in the environment.

The 41S+ uses real-time fusion parameter control by analyzing the fiber brightness intensity during splicing. This contributes to stable, low-loss splice results.

Analyzing the fiber’s brightness intensity

Active Blade Management Technology

1. Active Blade rotation by motor

The 41S+ and CT50 fiber cleaver are equipped with wireless data connectivity. This capability allows automatic cleaver blade rotation when the 41S+ judges the blade is worn.

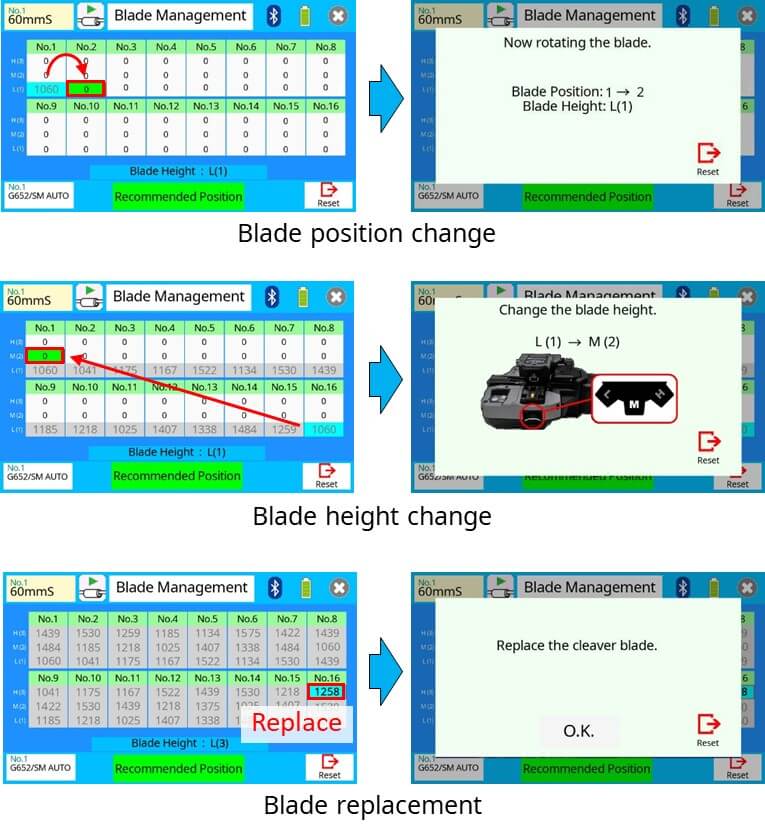

2. Active Blade life management

The 41S+ displays the remaining blade life and informs the user when a blade height change, blade position change, or new blade is required.

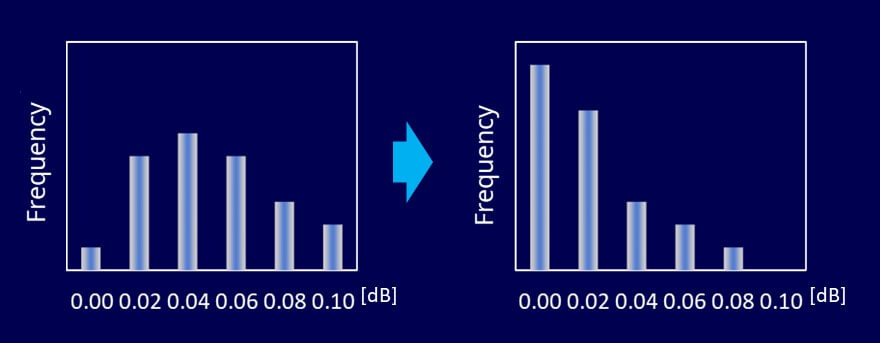

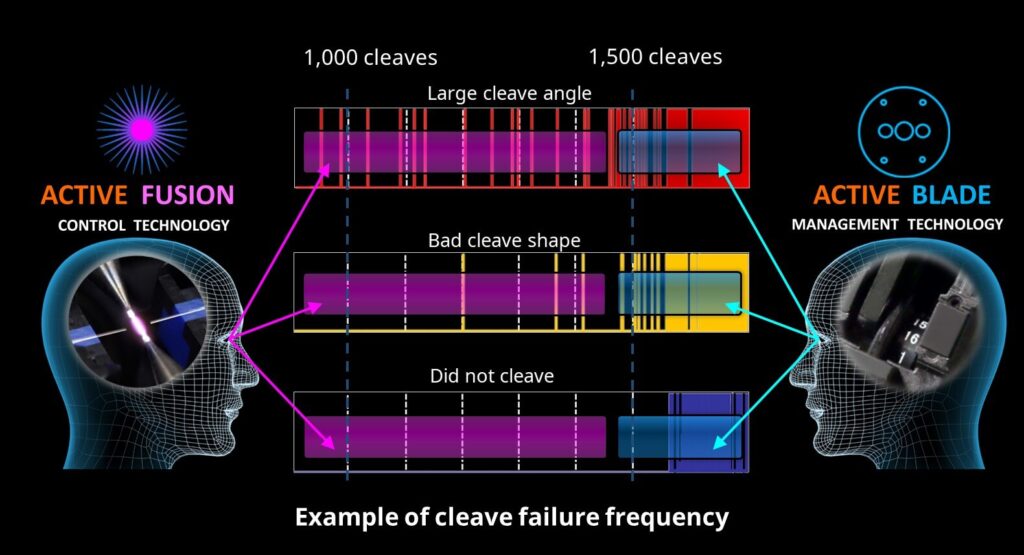

Enhanced Splice Quality

The graphs below show the number of cleaves on the horizontal line with frequency of large cleave angle, bad cleave shape and failure to cleave. When the frequency of large cleave angle or other cleave problems increases, Active Blade Management Technology can detect this increasing ratio of poor cleaves and rotate the blade position automatically. Active Blade Management Technology therefore significantly reduces the frequency of poor quality cleaves. Even when a poor cleave is detected, the 41S+ compensates by using Active Fusion Control Technology to apply optimized fusion to reduce the incidence of high splice loss.

By using these 2 key technologies together, the 41S+ minimizes the occurrence of high splice loss and greatly reduces the need for rework and re-splicing.

User Friendly

1. Easy Fiber Protection Sleeve Positioning

The shape of the sheath clamp is optimized for the 60mm length protection sleeve. The length from the splice point to the edge of the sheath clamp is 30mm. Therefore, it is easy to center the protection sleeve over the splice by using your finger as the reference point.

2. Universal Tube Heater

The 41S+ fusion splicer can accommodate splice sleeves with a diameter of up to 6.0mm. Therefore, it supports a wide range of protection sleeve sizes.

3. Easy replacement of consumable parts

3-1 Tool-less Electrodes replacement

The 41S+ electrodes comes as an assembly including electrode mounting fixture and thumb screw. The thumb screw is easily loosened or tightened by hand without tools. This enables easy electrode replacement.

Electrodes replacement without tools

3-2 User replaceable blade and rubber clamps

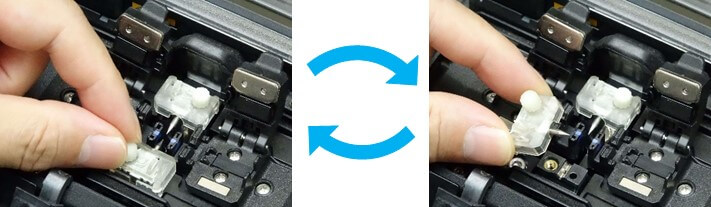

The CT50 fiber cleaver has a user replaceable blade and rubber clamps – there’s no need to send the device to a service center for blade or clamp replacement.

Replaceable rubber clamps

Replaceable blade

4. Carrying Case

There are multiple ways to utilize the 41S+ carrying case. The 41S+ is ready to use just by opening the case, but the splicer with an included work tray can also be removed. The tray can be placed on top of the carrying case or other work surface, mounted it on a tripod, etc.

5. Work Tray

The work tray has a drawer which can slide open to expand the work area. The tray has convenient features such as a recess to lock an included alcohol dispensing bottle in place to prevent it from falling.

SIMILAR PRODUCTS

The RS02 is designed and developed with emphasis on operability and usability where less force is required for the stripping process. Furthermore wireless link with smartphones for operational parameters adjustment. These fiber stripping tools are also compatible with stripping Fujikura latest Spider Web RibbonTM ,which consists of optical fibers (with a coating diameter of 250μm or 200 μm) fixed intermittently.

Item Successfully Added to Cart

The CT50 offers enhanced drop impact resistance compared to other existing cleavers and allows workers to replace the cleaving blade, providing customers with a drastic reduction in handling time and maintenance costs. The CT50 changes the position of the cleaving blade automatically and in accordance with the condition of the cleaving state of optical fibers on a fusion splicer through wireless communication. In addition,the CT50 can complete cleaving works including scrap collection, with a single-step.

Item Successfully Added to Cart

The function is to support user to transfer the drop cable easily from splicing area to heating module.

Item Successfully Added to Cart

The visual fault identifier FVI-01 is a miniature red-laser light source. The red light generated from FVI-01 will be identified at the break point, sharp-bend or high loss connection in coating fiber or fiber cord.

Item Successfully Added to Cart

- TMM Telekom Makine Madencilik San. Ve Tic.Ltd.Şti is an international company serving the international market for the various needs of its customers.

- Contact

- Contact Form

- Send E-mail

- Follow Us

_927163e5-d1b4-4309-8b9b-aac7fc87445d.png)

_5df15f60-a573-4570-87b1-b68674f7700c.png)

- Call Us

Zinc/Zn

Zinc/Zn

Specification Sheet

Specification Sheet